Food & Beverage

Interface detection

- 0.0005 – 80% solids content

- Optimize set-up times

- Optimize CIP cleaning cycles

- Reduce waste

- Detection of leaking valves

Many dairies operate Clean in Place (CIP) and product change-over cycles without adequate instrumentation. Product interfaces are often controlled using fixed time or volume based calculations using manual verification where safety margins ensure the product will always be at the desired concentration prior to further processing. Unnecessarily long product interfaces resulting from a lack of real time process data results in substantial waste – lost product, process downtime and waste treatment costs.

Knowledge of the actual concentration of the dairy product in real time will eliminate costly guess work and result in significant and substantial cost reduction. CIP cycles can be optimized, product set-up times can be significantly reduced and product quality can be improved resulting in an increased profitability for the dairy, a better environment through reduced waste and happier customers.

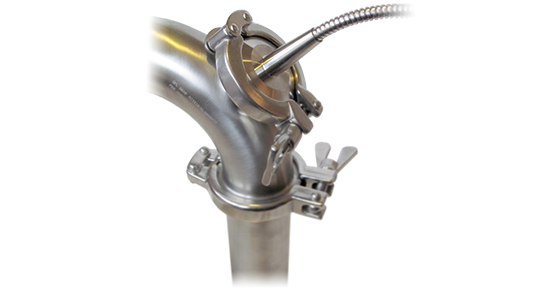

The Kemtrak NBP007 utilizes high resolution VIS-NIR backscatter reflectance measurements for the accurate determination of the total solids content. Measurements are undertaken continuously and in real time using a hygienic TriClamp process connection that is engineered to withstand the high temperatures and chemicals present in CIP & SIP cleaning cycles. The sanitary backscatter probe is manufactured in 316L stainless steel with a robust scratch resistant sapphire window. The highly polished unbroken probe surface ensures freedom from fouling and suitability for sanitary applications.

The Kemtrak NBP007 is an optical in-line analyzer suitable for continuous total solids content monitoring of dairy products including milk, cream and cultured dairy products such as yoghurt and cream cheese.

Traditional turbidity based optical measurement instruments lack resolution and are not reliable at concentrations above 1% suspended solids due to the high optical density of the process media. This limitation is overcome with the Kemtrak NBP007 and for the first time the operator can monitor and have complete control over their dairy process at any concentration.

Interface detection Application Note

NBP007 Product Brochure

Fiber optics are used to connect to the sanitary backscatter probe which contains no electronic components. The standard probe will withstand constant operating temperatures of 120°C / 248°F making it suitable for high temperature SIP cycles. Higher temperature probes are also available.

Contact a Kemtrak sales representative for additional information.